People and Projects

| Mold filling and solidification of low pressure casting and centrifugal casting | Savithri Sivaraman,with Roschen Sasikumar and Elizabeth Jacob |

|

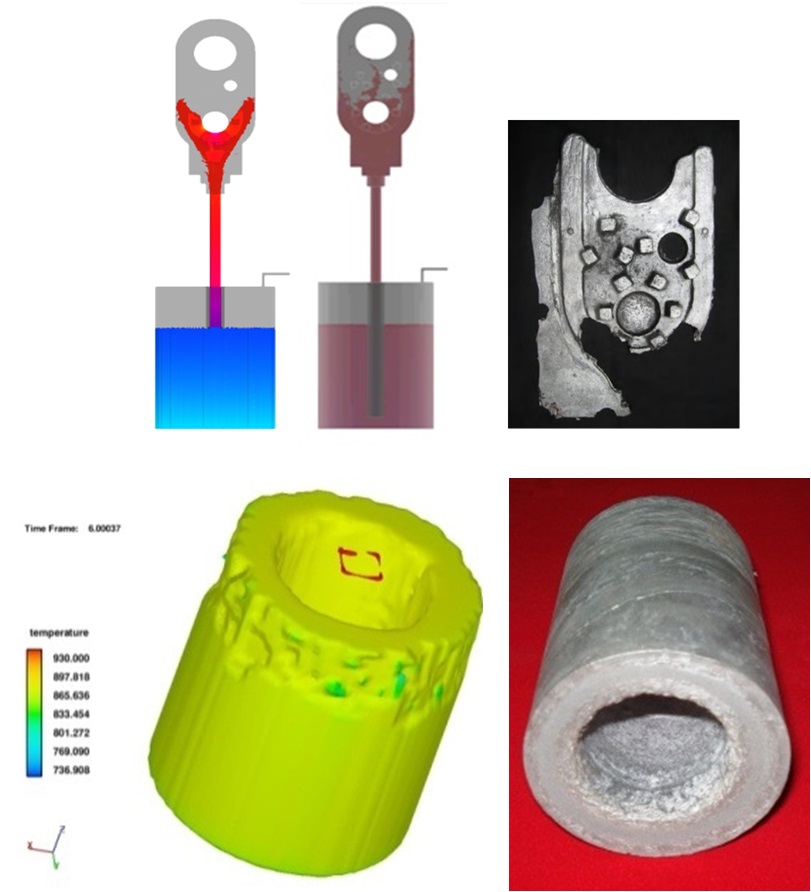

Background : Low pressure casting for making thin walled parts and centrifugal casting used for producing near net shaped components with improved properties are two important processes. Pressure distribution and fluid flow plays a major role in these processes and understanding the complex flow phenomenon is essential for the production of defect free castings. An existing CFD code was used in this project to understand the effect of various process conditions on the casting quality Methods : For the present simulation, a particular thin walled casting component was chosen. The CAD file of this component is imported in CFD software as a STL file and a finite difference mesh is generated using the mesh building option. A356 aluminum alloy is used for the casting component. GMRES method is chosen for solving the discretized fluid flow equations. The convergence criteria chosen for the present simulation is mass convergence and the tolerance limit is set to 1.0e-04. In a similar way mold filling simulation and solidification simulation of centrifugal casting process for producing hollow cylinder and ring components made of A356 Aluminium alloy was carried out. Results : The adjacent figures shows some typical results along with experimental results for both these processes. |

|