Setting up an E-Foundry Cell

|

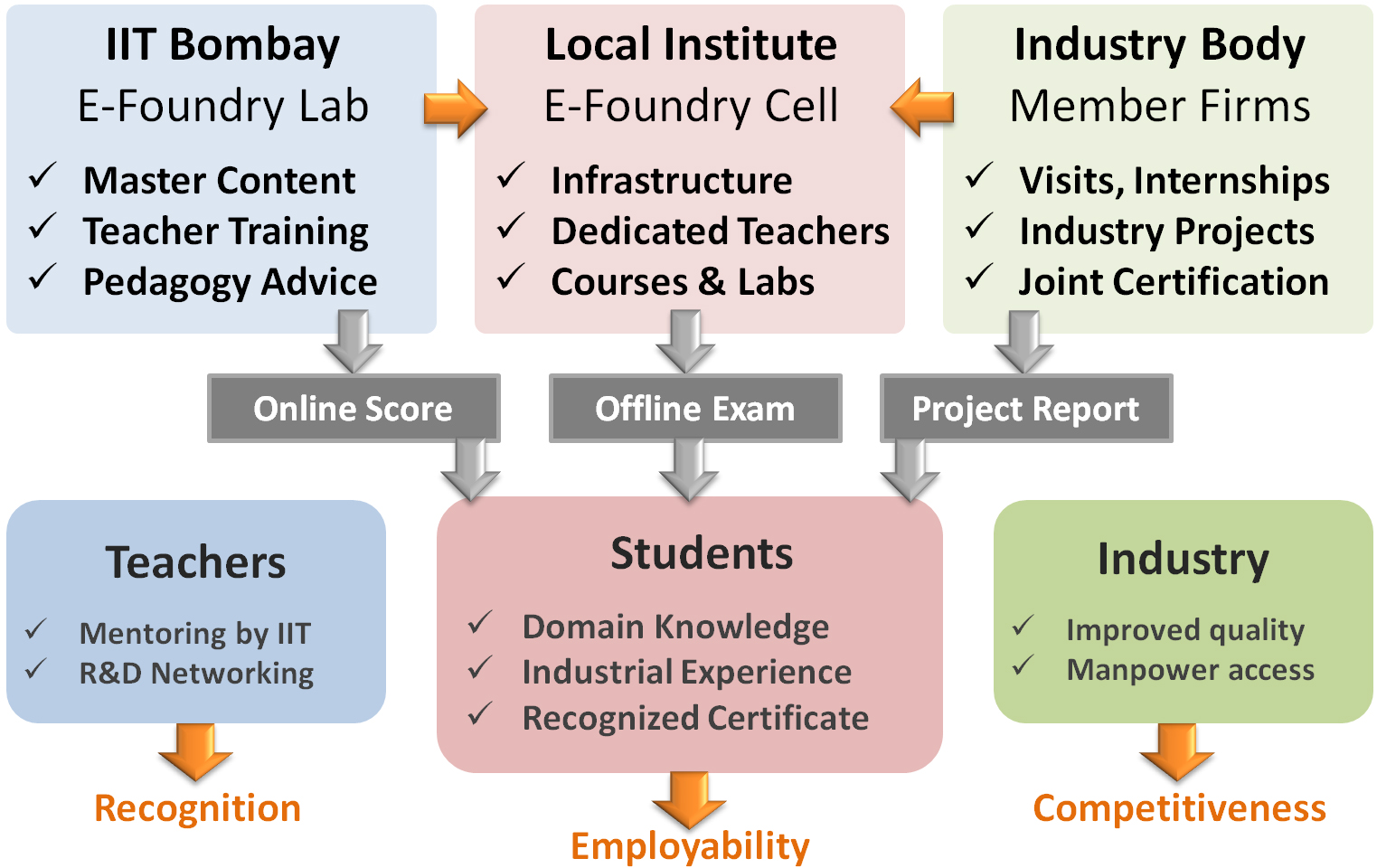

Interested institutes can set up an E-Foundry Cell to support theory courses, laboratory exercises, student projects, and research work. This can also be used for industry interaction through training programmes and collaborative projects. A basic level E-Foundry Cell can be set up without incurring any additional cost of hardware or software, by using the resources freely available in this site. Teachers can use the lesson videos, slides PDF and animations to make their classes more interesting. The quizzes and tutorials can be used for student evaluation. The online solidification simulation facility can be used to run a lab exercise of feeder design optimization, and also to explore industry projects. The library of technical papers and the researcher network are useful for supporting R&D projects. An intermediate level E-Foundry Centre can acquire academic versions of 3D solid modelling, casting design and simulation software with network license to support several users simultaneously. This can be used for multiple lab exercises including core and mold cavity layout; feeder design and optimization by solidification simulation; and gating design and optimization by flow+solidification simulation. This can also be used for industrial consultancy projects. An advanced level E-Foundry Centre of Excellence can have facilities for experimental research, in addition to the casting software mentioned above. This includes 3D printing system; rapid tooling unit; clean moulding unit; melting and pouring unit; thermal data acquisition; geometric, surface and internal quality inspection; microstructure characterization; and mechanical property testing. Other supporting facilities include training room, video conferencing, and mini-library. Tie-up with industry will enable joint projects and certification of students trained in the Centre. |

|