Simulation Lab

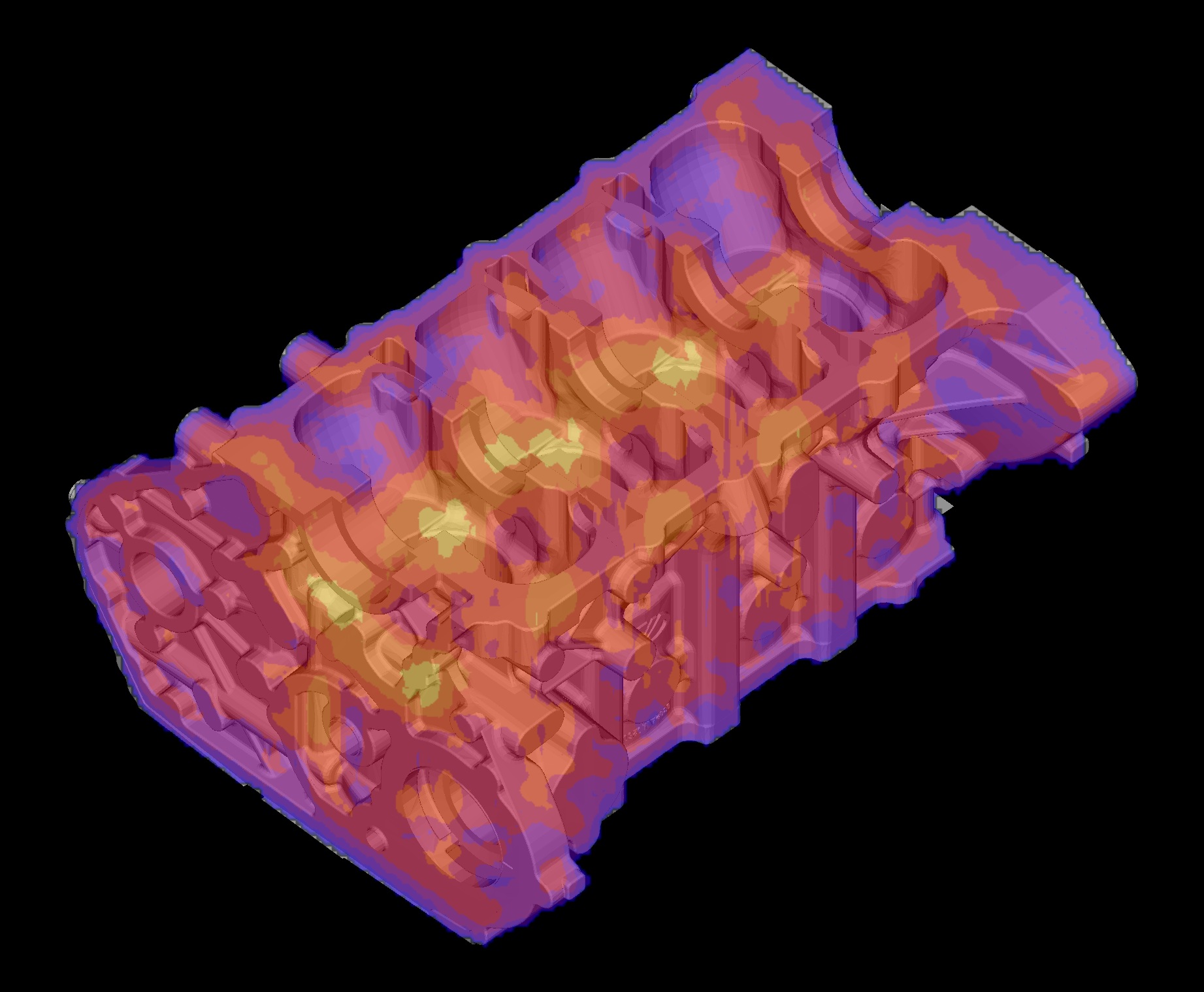

| Casting temperatures at the end of solidification |

Please login to simulate! |

CASTING SIMULATION is a powerful tool to visualize progressive solidification of molten metal inside a mold cavity. It helps in identifying hot spots (yellow regions), which manifest as shrinkage porosity defects. The defect is usually eliminated by connecting a feeder, which is designed to solidify later than the hot spot. It supplies liquid metal to compensate the volumetric contraction at the hot spot. Feeder is cut-off and recycled, hence its size has to be optimized to ensure high yield.

STEPS

|