People and Projects

|

Casting solidification feed-paths: Modeling, Computation and Applications Mayur Sutaria |

|

|

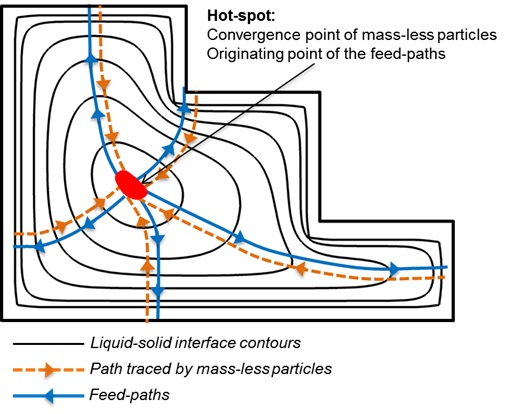

Background : The feeding mechanism during casting solidification can be directly visualized by computing and plotting the path along which molten feed metal moves to compensate volumetric contraction. The soundness of a cast part depends on an uninterrupted flow of molten feed metal along feed-paths. Methods : The casting solidifies progressively from the mould walls until it converges to isolated last solidifying points in the mould-cavity, known as hot-spots. The liquid-solid interface converges at hot-spots, forming a singularity. A physics-based Level-set Method (LSM) and a hybrid Gradient Vector Method (GVM) were developed to compute the feed-paths by continuously tracing interface evolution with the help of mass-less particles in the normal direction. Results : Location of the hot-spot was obtained as the point at which the advection of mass-less particles converged or in other word the point from where feed-paths originated as shown in Fig. 1 . Conclusion : The GVM was found to be about ten times faster than the LSM and FEM. The GVM allows computation of a single feed-path along which feeding to a desired location occurs. This feature facilitated quick visualisation of feeding mechanism in a local region. The results were verified by performing experiments, and a good correlation was observed between computed and experimental location of shrinkage porosity defect. |

|